Maximize Efficiency With The Comprehensive Cat Undercarriage Wear Chart – Click Now!

Cat Undercarriage Wear Chart: A Comprehensive Guide for Equipment Owners

Introduction

Welcome, Good Peoples! As a Fashion Enthusiast, you understand the importance of keeping your equipment in top shape. One crucial aspect of maintenance is monitoring the wear and tear of your cat undercarriage. In this article, we will provide you with a detailed cat undercarriage wear chart to help you assess the condition of your equipment accurately.

2 Picture Gallery: Maximize Efficiency With The Comprehensive Cat Undercarriage Wear Chart – Click Now!

Cat undercarriage wear refers to the deterioration of components such as tracks, rollers, idlers, and sprockets on your heavy machinery. By utilizing a wear chart, you can monitor the wear levels and plan for timely replacements, avoiding costly breakdowns and optimizing the performance of your equipment.

Now, let’s dive into the details of the cat undercarriage wear chart and explore its significance in equipment maintenance.

The Cat Undercarriage Wear Chart

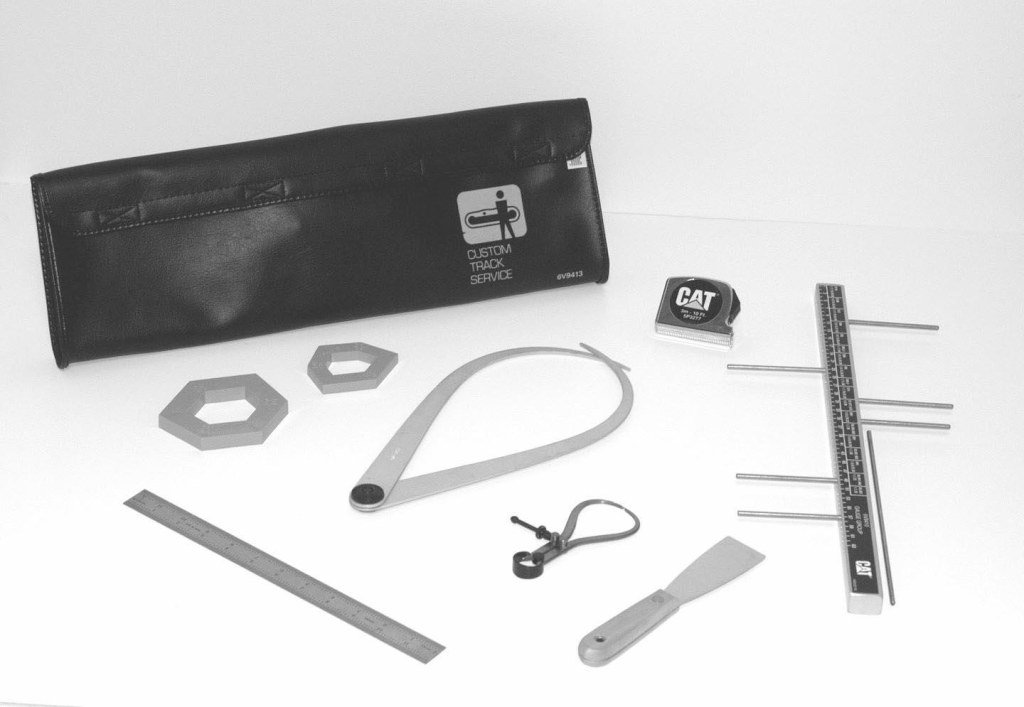

Image Source: isu.pub

The cat undercarriage wear chart is a comprehensive tool that provides detailed information about the wear levels of various undercarriage components. It allows you to assess the condition of your equipment and determine when specific parts need replacement. The wear chart typically includes measurements in percentage, indicating the remaining life of each component.

To use the wear chart effectively, you should measure the wear levels regularly and compare them with the recommended limits provided by the manufacturer. By doing so, you can identify potential issues early on and take proactive measures to prevent further damage.

What is Cat Undercarriage Wear?

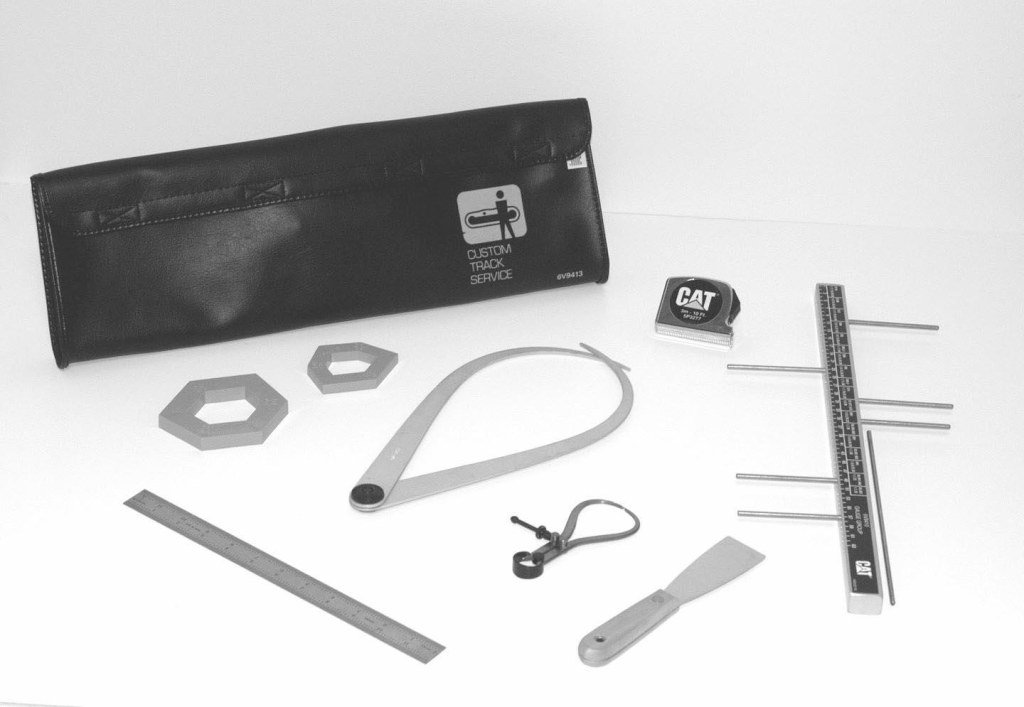

Image Source: scene7.com

Undercarriage wear refers to the gradual deterioration of components that make up the undercarriage of your heavy equipment. This wear is primarily caused by the friction between the components and the terrain they operate on. Over time, this friction leads to material loss, affecting the overall performance and lifespan of the equipment.

Understanding the causes and effects of undercarriage wear is crucial for equipment owners, as it helps them devise appropriate maintenance strategies and ensure optimal performance.

Who Should Monitor Cat Undercarriage Wear?

Monitoring cat undercarriage wear is essential for anyone who owns or operates heavy equipment. From construction companies and mining operations to agricultural businesses, proper maintenance of the undercarriage is crucial for maximizing productivity and minimizing downtime.

Equipment owners, fleet managers, and operators should all be familiar with the cat undercarriage wear chart to ensure timely replacements and reduce overall operating costs.

When Should You Refer to the Cat Undercarriage Wear Chart?

Regularly referring to the cat undercarriage wear chart is essential during routine maintenance inspections. It is recommended to check the wear levels of the undercarriage components at specific intervals, depending on the type and intensity of equipment usage.

By incorporating wear chart assessments into your maintenance schedule, you can stay ahead of potential issues, plan for replacements, and significantly extend the lifespan of your undercarriage.

Where Can You Access a Cat Undercarriage Wear Chart?

Cat undercarriage wear charts are readily available from authorized dealers, manufacturers, or online resources. You can also consult your equipment manual or reach out to your local dealer for guidance on obtaining a reliable wear chart.

Ensure that the wear chart you use is specific to your equipment model and follow the manufacturer’s guidelines to ensure accurate assessments.

Why Is the Cat Undercarriage Wear Chart Important?

The cat undercarriage wear chart is vital for equipment owners as it provides a standardized method for assessing and tracking the condition of their undercarriage components. By monitoring wear levels regularly, owners can identify potential problems before they escalate, avoiding costly downtime and repairs.

Moreover, the wear chart helps optimize equipment performance by ensuring timely replacements. Components that are excessively worn or damaged can lead to reduced traction, increased fuel consumption, and uneven wear on other parts. By replacing these components based on wear chart analysis, equipment owners can maintain optimal performance levels and minimize overall operating costs.

How to Use the Cat Undercarriage Wear Chart

Using the cat undercarriage wear chart involves several steps to accurately assess the condition of your equipment. Here is a step-by-step guide:

Start by measuring the wear levels of each undercarriage component, including the tracks, rollers, idlers, and sprockets. Use the recommended measurement technique provided by the manufacturer.

Refer to the wear chart specific to your equipment model and compare the measured wear levels with the recommended limits.

If the wear levels are within the acceptable range, continue monitoring regularly and plan for replacements when they approach the limits.

If the wear levels exceed the recommended limits, schedule immediate replacements to prevent further damage and ensure optimal performance.

Record the wear levels and replacement dates for future reference and analysis.

Repeat the process at regular intervals to maintain accurate assessments and make informed decisions regarding maintenance and replacements.

Advantages and Disadvantages of Cat Undercarriage Wear Chart

Advantages

1. Proactive Maintenance: The wear chart allows equipment owners to proactively monitor the condition of their undercarriage components, preventing unexpected breakdowns and costly repairs.

2. Cost Savings: By identifying worn components early on, owners can plan for replacements, minimizing downtime and reducing overall operating costs.

3. Optimal Performance: Regular wear chart assessments ensure that equipment operates at peak performance levels, maximizing productivity and fuel efficiency.

4. Data-Driven Decisions: The wear chart provides tangible data that can aid in making informed decisions regarding maintenance schedules and replacements.

5. Increased Lifespan: By closely monitoring wear levels, equipment owners can extend the lifespan of their undercarriage, avoiding premature replacements.

Disadvantages

1. Initial Investment: Implementing a comprehensive wear chart monitoring system may require an initial investment in training, tools, and software.

2. Time-Consuming: Regular wear chart assessments involve measuring multiple components and comparing the results, which can be time-consuming.

3. Skill Requirement: Accurate wear chart analysis requires knowledge and expertise in equipment maintenance and measurement techniques.

Frequently Asked Questions (FAQs)

1. Can I use a generic wear chart for my equipment?

No, it is crucial to use a wear chart specific to your equipment model. Each machine has unique specifications and wear limits.

2. How often should I measure the wear levels of my undercarriage components?

The frequency of measurements depends on the intensity and type of equipment usage. Consult the manufacturer’s guidelines or your equipment manual for specific recommendations.

3. What are the consequences of ignoring undercarriage wear?

Ignoring undercarriage wear can lead to reduced equipment performance, increased fuel consumption, and potential breakdowns, resulting in costly repairs and downtime.

4. Can I replace individual components instead of the entire undercarriage?

Yes, in most cases, individual components can be replaced as long as they meet the manufacturer’s specifications and recommended wear limits.

5. Is it possible to extend the lifespan of my undercarriage through proper maintenance?

Absolutely! Regular maintenance, including timely replacements based on wear chart analysis, can significantly extend the lifespan of your undercarriage, saving you money in the long run.

Conclusion

By utilizing the cat undercarriage wear chart, equipment owners can ensure the optimal performance and longevity of their heavy machinery. Regular wear chart assessments enable proactive maintenance, cost savings, and data-driven decisions. Remember to use a wear chart specific to your equipment model and consult the manufacturer’s guidelines for accurate assessments. Stay on top of your undercarriage wear levels, and your equipment will thank you with enhanced productivity and reduced operating costs.

Final Remarks

As a final note, always prioritize safety when conducting maintenance inspections or replacing undercarriage components. Follow the manufacturer’s instructions, wear appropriate personal protective equipment, and seek professional assistance when needed. Proper maintenance, backed by the cat undercarriage wear chart, ensures the longevity of your equipment and the well-being of your team. Take care and happy equipment ownership!

This post topic: Wear